Rescue Mission: How Reverse Logistics Can Save Millions of Shoes

Innovation

Nike's refurbishment programme gives new life to once-discarded sneakers.

Presented by Move to Zero: Nike's Journey towards zero carbon and zero waste to help protect the future of sport.

Ever wonder what happens to the shoes you send back?

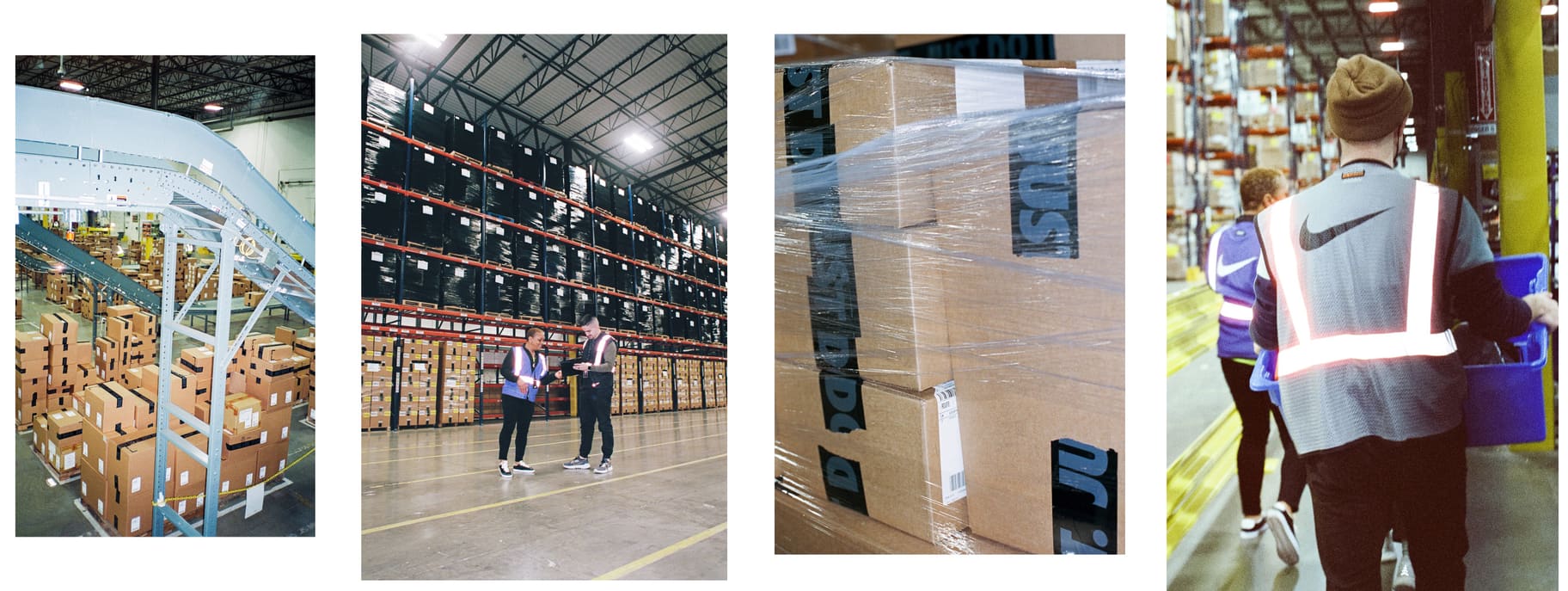

For millions of pairs of Nikes, all roads lead to Nike Rebound, a sprawling reverse logistics facility in Lebanon, Indiana.

"Rebound is where we process all Nike returns in North America, so it's a big place", says Valerie Nash, inbound operations manager.

Nike Rebound processes thousands of returns a day. Swipe to see the people like Valerie Nash (left) and Fabian Garcia who make it all possible.

Nike Rebound is huge—roughly 20 American football fields—because it processes thousands of returns a day. People like

Valerie Nash (left) and Fabian Garcia make it all possible.

She's not joking. The three-storey facility is 1.1 million square feet (that's roughly 20 American football fields) and receives thousands of returns a day—some from at-home athletes like you, some from our many retailer partners who sell Nike products. Some pairs are well-worn and muddy, others might have just been the wrong size. No matter who, what or why, it all lands at Rebound.

Shuttling in and organising that number of returns is just part of the reverse logistics process. The next step is deciding what to do with it all.

Different Return Journeys

Never-been-worn products in mint condition, with no visible signs of wear, go straight back into stock for online purchases or deliveries to stores.

But those shoes you ran in before deciding to return them? Well, they're a bit dirty from the road. Rebound team members might try giving them a quick clean during inspection, but sometimes that's not enough to restore the shoes to mint condition.

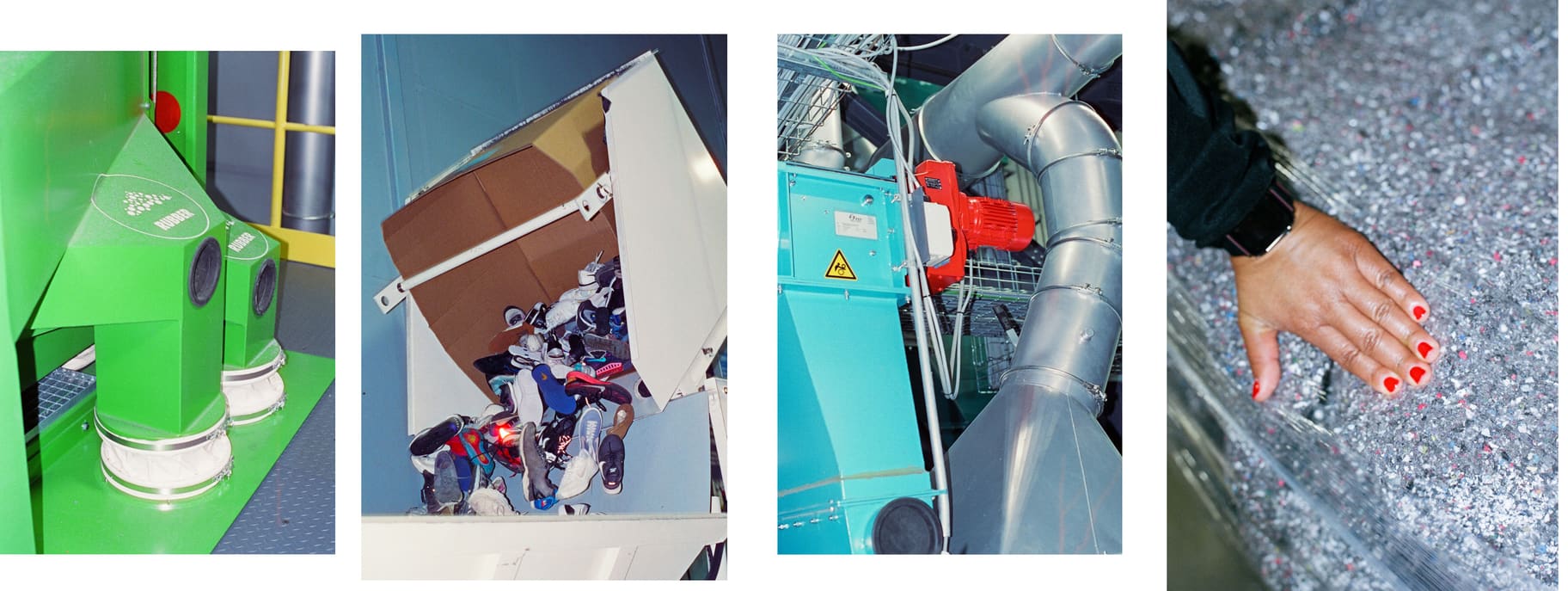

Before the refurbishment programme started, all returned shoes with signs of wear—no matter how severe—used to be shredded with Nike Grind machines pictured in this carousel.

All returned shoes with signs of wear—no matter how severe—used to be shredded with Nike Grind machines like the

ones seen here. But the team at Rebound knew they had the opportunity to give a lot of shoes a second chance.

In the past, all slightly worn shoes like this were shredded as part of Nike Grind, our shoe recycling programme that started back in 1992 and supplies raw material for sport court surfaces, tech accessories, carpet padding and more. While some worn-down shoes deemed no longer functional still meet this end, the Rebound team knew that tons of almost-perfect pairs just needed a little extra love.

If a quick wipe down on the inspection line doesn't cut it, shoes with slight signs of wear are refurbished.

The refurbishment team's trained technicians give thousands of new shoes a second chance each day.

Ready For Refurbishment

Enter Nike Refurbished, a programme that rescues shoes that might otherwise be discarded—more than 225,000 pairs of them to date—and puts them back on the shelf of Nike stores at a reduced price.

"Nike Refurbished is like us rebirthing the product; we're giving it life again. We clean it up, make it look like new, then put it back into the marketplace".

Valerie Nash

Inbound Operations Manager

"Nike Refurbished is like us rebirthing the

product; we're giving it life again. We clean

it up, make it look like new, then put it back

into the marketplace".

Valerie Nash

Inbound Operations Manager

If a quick wipe down during initial inspection doesn't cut it, Rebound team members place products in bins that zoom around on miles of conveyor belts to the warehouse within a warehouse that is the Refurbishment headquarters.

There, a team of trained technicians greet the slightly worn shoes and work in perfect harmony to process them.

"Every shoe is unique", says Fabian Garcia, sustainability process manager. "So we use a variety of tools to get it as close to its original state as possible".

Trained technicians give thousands of new shoes a second chance each day. Swipe to see details of their process.

The process of pulling shoes off the inspection line to be refurbished started in 2021. Today, more than 225,000 pairs

have made it back onto shelves.

Each workstation is stocked with wipes, brushes, stain remover, disinfectant spray and even an assortment of picks that dislodge pesky pebbles stuck in the soles. Technicians wield those tools to scrub, buff and spray returned shoes until they're fresh enough to join someone's collection.

Once they've finished, technicians pass shoes to their teammates who sort, box and dispatch them to stores.

Anthony Clark, outbound operations manager, puts it in perspective. "Have you ever seen a 50-foot lorry driving down the motorway?" he asks. "One of those can hold around 5,000 boxes of shoes. That's about how many pairs this team will refurbish and reintroduce to people every day".

The process of pulling shoes off the inspection line to be refurbished started in 2021.

Next time you're in a Nike store, keep your eyes peeled for Refurbished boxes like this one. The team's goal is to get

them into all US stores. Maybe yours will be next.

Where To Next?

Articulated lorries filled with refurbished shoes head to select Nike stores across the US. There, you can find them in the "Nike Refurbished" shoe boxes marked as either "like new", "gently worn" or "cosmetically flawed".

"This is just the beginning. Our goal is to have Nike Refurbished in every store".

Anthony Clark

Outbound Operations Manager

"This is just the beginning. Our goal is to

have Nike Refurbished in every store".

Anthony Clark

Outbound Operations Manager

That goal may not be too far off. "At the beginning of 2021, we launched the programme in three stores", says Fabian. "One year later, we're sending refurbished shoes to 30 stores. We're now expanding our capacity so we can process even more of the unstockable units across our North America supply chain".

Just think, your next return could be part of the millions of units the Rebound team hopes to process this year—and somebody's new favourite pair.

For more: Visit Nike.com/Sustainability to follow each step in our journey and discover new ways we can Move to Zero carbon and zero waste together.

Photography: Ariel Fisher

Words: Rebecca Coolidge